- Saturday to Thursday

8AM - 8PM

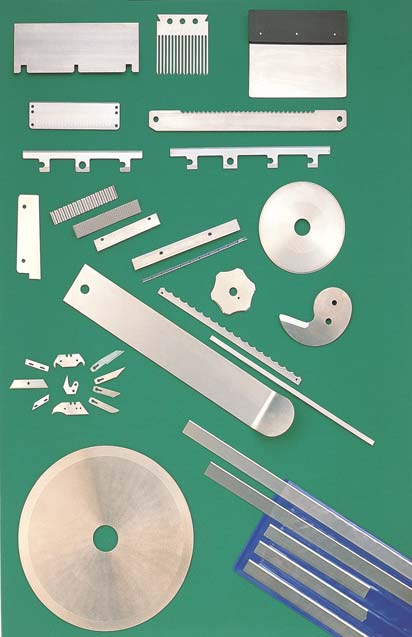

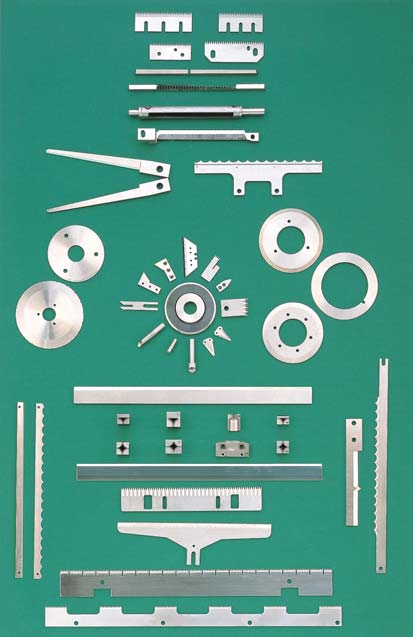

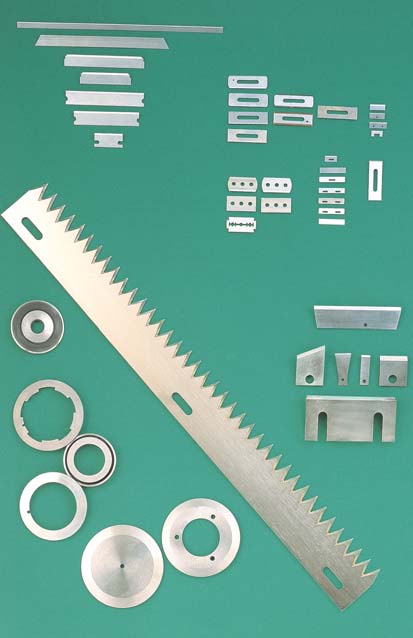

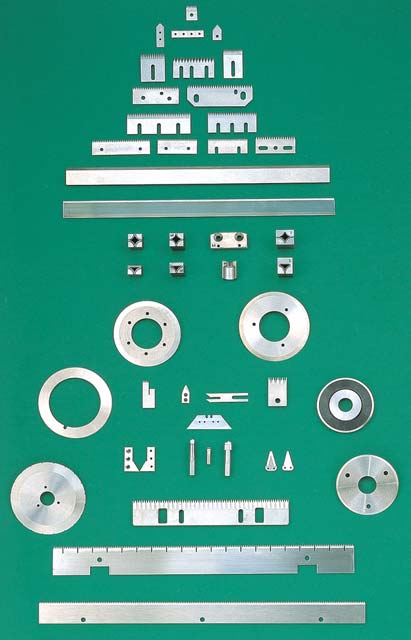

Quality and visual appearance become increasingly important as purchasing criteria for groceries. Exercising maximum care in fabrication is the precondition for efficient food processing and packaging and for its effective sales presentation. Accuracy and Care are also two of the key criteria for the production of our industrial knives as well as quality and flexibility – since the required knife can be delivered for every branch of production within the food industry, may it be meat, fish, vegetables, confectionaries, bread, kebab or cheese and dairy products.

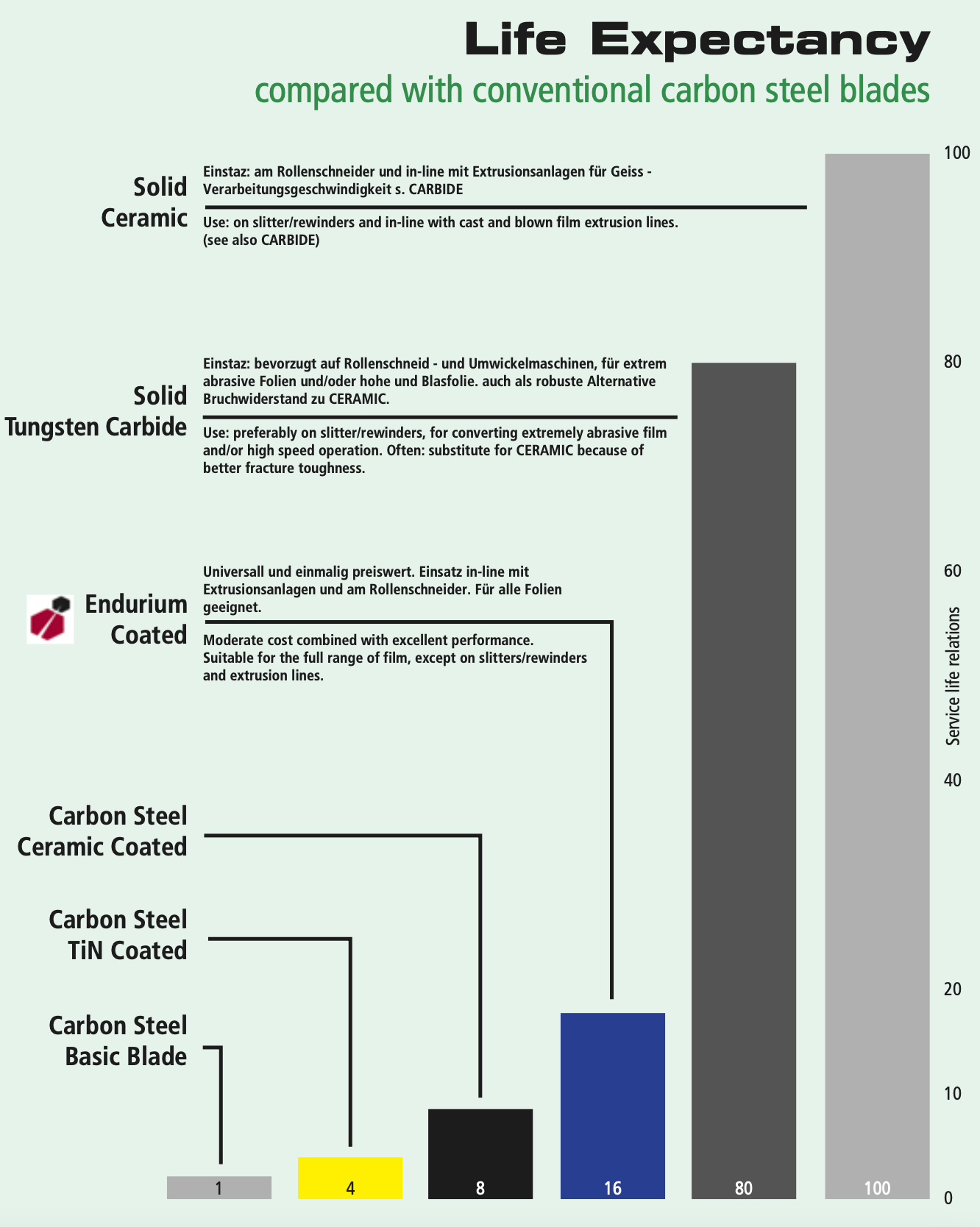

Converting man made film and fibre products requires an array of cutting requirements to effectively slit, perforate, chop and recycle the end product. Our unique range of industrial razor blades are used by the world’s largest manufactures to ensure the consistency and quality of their products.

Our investment in innovation means that we are always at the fore-front of technology when it comes to preparing machine knives for processing the material into bags, sacks, tape, labels and sachets.

We supply a wide range of knives for use in the print and sealing areas. These include high precision vacuum punches, fly knives, serrated web press knives, film cut off knives, core cutters, crush cutters, dish slitters, tape sealers and bottom knives.

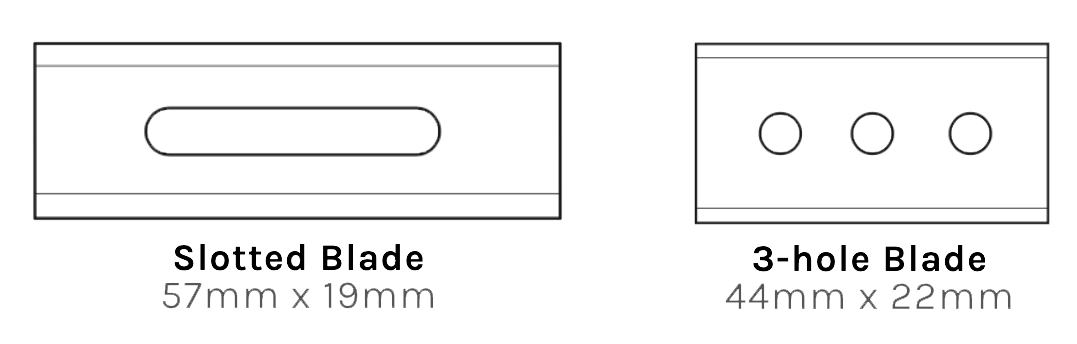

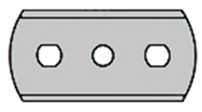

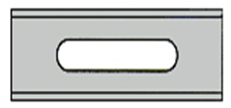

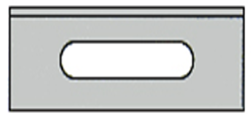

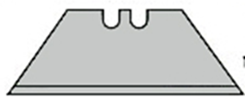

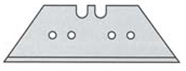

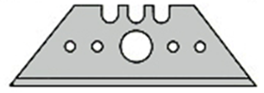

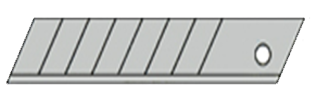

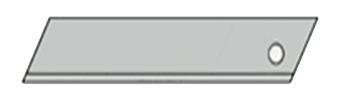

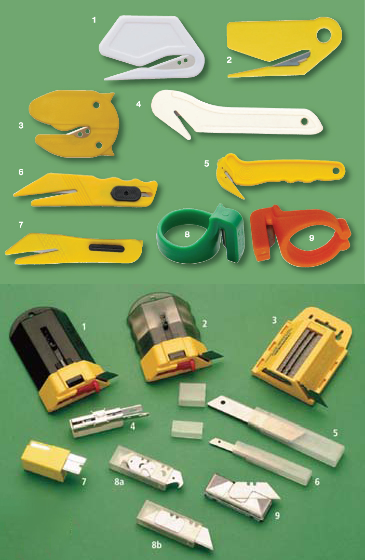

We are known for supplying the world’s best industrial razor blades. By making precision ground strip to the most exacting tolerances the company’s products are able to cope with the demands of modern production methods and all trade requirements. We offer an extensive standard blade range in carbon, stainless and high grade alloys, complemented by the latest in long life, low friction PVD coatings, powder technology carbide and ceramic blades. In addition, our utility range can be supplied branded with your company name and logo, on the body, the blade or the packaging and is offered in a selection of presentation, utilitarian, and safety packaging.

Thickness: 0.004" 0.006" 0.008" 0.010"/0.1mm 0.15mm 0.2mm 0.25mm 0.3mm

Thickness: 0.005" 0.008" 0.01" 0.016"/0.13mm 0.2mm 0.25mm 0.4mm

Thickness: 0.015"/0.38mm

Thickness: 0.015"/0.38mm

Thickness: 0.025"/0.64mm

Thickness: 0.025"/0.64mm

Thickness: 0.025"/0.64mm

Thickness: 0.020"/0.5mm

Thickness: 0.02"/0.38mm

Thickness: 0.020"/0.5mm

Thickness: 0.02"/0.38mm

The hand held utility knives are designed for today’s environment. Strong, durable, uncomplicated and effective whilst remaining easy on the pocket. Where safety is an issue we have a multitude of different approaches from spring loaded designs to hidden blades and restricted apertures to ensure that every job can be completed quickly and safely without damage to product or person.

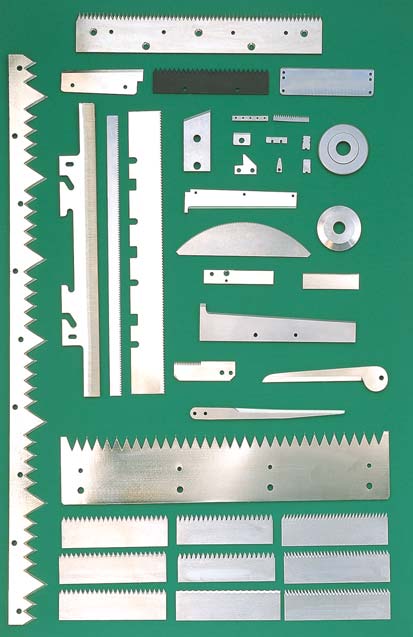

We develop prototypes and competitive short run products for machine builders, end users and

multinationals alike. Investment in modern manufacturing equipment means that production runs of up

to one million blades can be delivered on time and correct to specifications.

Straights, zig zags, flat circles, punches, coiled strip, dish circulars, serrated strip,

granulators, pelletisers, tube cutters, serrated pieces are all available so if it cuts, slits,

slices, pierces, perforates, chops, chips, dices, scrapes, mixes, folds, macerates or creases then

we can probably help you improve it.

WE MAKE ALL KINDS OF KNIVES AND BLADES TO SUIT CUSTOMER REQUIREMENTS.

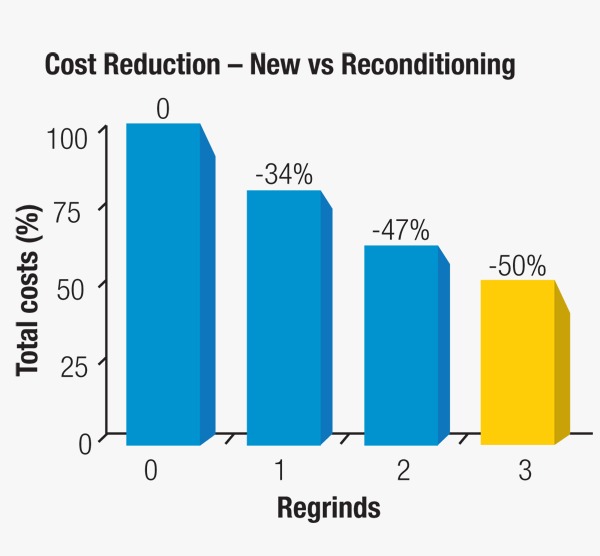

The regrinding service significantly reduces tooling costs over buying new tools. Our customers benefit from super abrasive grinding expertise providing high accuracy and quality. All tools are subject to stringent quality and performance checking and testing to ensure best results.